Product

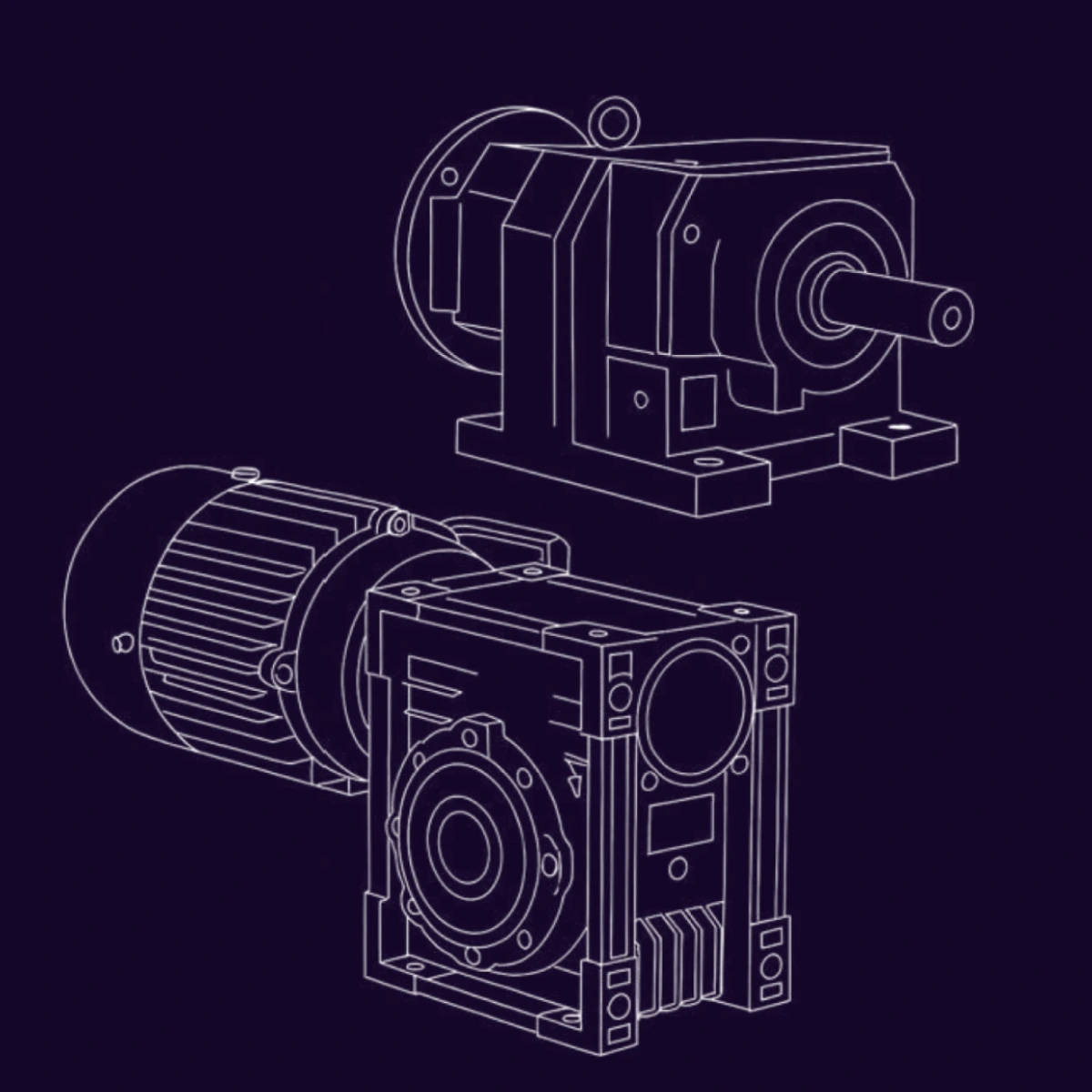

Gear Drives & Motors

Industrial gear drives and motor assemblies for OEMs

For over 50 years, Brown GearTech has supplied OEMs with rugged, efficient gear drives and motor assemblies. Whether you require worm, helical, bevel, or compact motors, we integrate each into a complete package that’s designed around your machinery. Every unit is built in the UK, supported by fast technical advice, and adapted to your exact requirements.

From conveyors to crushers, our drives are trusted by OEMs where uptime, precision, and reliability cannot be compromised.

Key solutions

1.

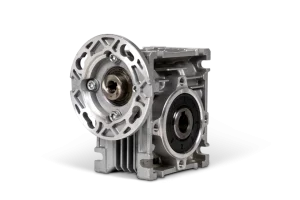

Worm gear reducers:

Compact, high-torque reducers with ratios 5:1–100:1, configurable inputs, shafts and flanges

2.

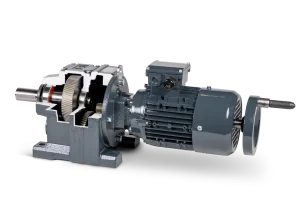

Helical drives:

High-efficiency drives up to 50,000 Nm, modular and adaptable

3.

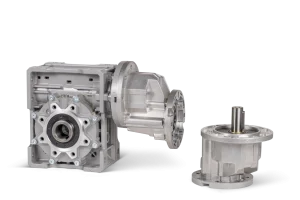

Spiral bevel gearboxes:

High-efficiency drives up to 50,000 Nm, modular and adaptable

4.

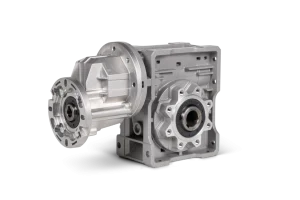

Compact geared motors:

AC/DC solutions from 3 W to 200 W for space-critical designs

5.

AC motors:

Reliable IE3/IE4 rated motors with options such as thermal protection or ATEX certification

Gear Drives & Motors Gallery

Why OEMs choose our drives:

Every gearbox can be supplied with encoders, torque limiters, cooling kits or any other type of bespoke adaptation ensuring a complete package for your system.

- Supplied as integrated assemblies (gearbox + motor)

- Flexible, customisable, and compatible with legacy systems

- Built in the UK for short lead times and dependable quality

- Proven in demanding sectors: food, recycling, logistics, water treatment

gear drives & motors

Applications in practice

Our gear drives and motor assemblies are widely used across OEM machinery. In food production, they support conveyors, mixers, and packaging lines to ensure consistent performance. Recycling facilities depend on them for crushers, shredders, and sorting systems, maintaining throughput even under heavy workloads. Water treatment plants use bevel gearboxes for reliable, long-term operation. In logistics and material handling, compact geared motors fit into space-constrained areas while maintaining efficient operation.

Contact Our TeamFAQs

Can these drives be retrofitted?

Food-grade gearboxes are designed with stainless steel housings, sealed lubrication, and smooth surfaces that prevent bacterial growth. They’re also built to handle high-pressure washdowns and resist chemical cleaners used in food plants.

What’s the typical lead time?

Food-grade gearboxes are designed with stainless steel housings, sealed lubrication, and smooth surfaces that prevent bacterial growth. They’re also built to handle high-pressure washdowns and resist chemical cleaners used in food plants.

Built for the long term

Every drive is engineered for long service life and supported with spares and technical advice. Many of our units remain in operation for decades, reducing downtime, avoiding waste, and keeping equipment running without the need for frequent replacement.

Talk To our team